Smartscan Ltd offers comprehensive machinery safety solutions for all its customers right through the machine safety life cycle, from an initial concept through safety standards, risk assessment, control system design and safety product supply, t- installation, commissioning and a comprehensive maintenance package.

Routine or preventative maintenance of safety products installed on the customer’s machines is an important area within the machine safety life cycle. There are of course many standard benefits to a routine maintenance schedule including extending the product life, early identification of potential problems and reduced machine downtime and its significant associated costs.

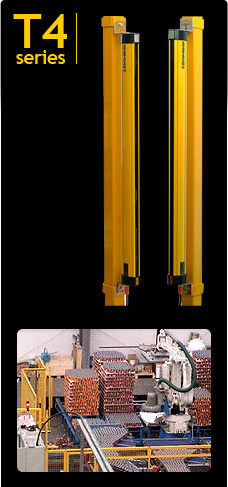

In many factory environments machine safety products are exposed to a variety of potentially damaging encounters from fork lift trucks and high pressure wash down to oil, grease and general damage from the day to day manufacturing processes. For example, with safety light curtains this can result in product being knocked out of alignment, fluid ingress, broken connectors and the degrading of the Perspex window covering the infra-red light beams with the subsequent reduction in operation.

Smartscan have been providing a routine maintenance package as part of its safety system solutions for over 10 years now and it is used by a number of large blue chip companies within the UK Food and Drink sector. The wealth of knowledge and practical experience we have developed in this area gives our customers additional reassurance of the work being carried out and down-to-earth help with application queries.

The Smartscan maintenance package involves a Smartscan approved engineer going on site to undertake planned maintenance of the Smartscan safety products covered by the maintenance contract. The engineers will be competent and fully trained in Smartscan’s product range and on-site Health and Safety.

The maintenance package will include the following features:

- A full service report detailing the Smartscan safety product in use, the product status, positioning of the product and any work or repairs carried out. It will als- include a check list for all products detailing all the checks undertaken.

- A Certificate will be provided for assurance of the quality of the maintenance workmanship and compliance with the appropriate machine safety standards and legislation.

- Example maintenance checks for a safety light curtain include: Correct operation of the light curtains and accessories (remotes, relay control box, reset stations, cables etc.), Mechanical installation, Electrical installation, Stop-Circuit interface, EMC check from the supply voltage and application specific checks.

- While under a maintenance contract we will offer a loan guard if a guard has a problem that cannot be resolved on site. (Note: loan guards are only available for the current Smartscan range of products). Any repairs found necessary will be charged t- the customer but only following approval from the customer and confirmed by a Purchase Order number.

- Technical Help line open during office hours for application and technical product support.

The maintenance package will generally be scheduled on a yearly basis and carried out at a time t- suit the customer e.g. specific downtime periods. This may well involve the maintenance work being undertaken at the weekend.

Key benefits of the Smartscan maintenance package include:

- Helping to reduce costly unplanned downtime by ensuring that the safety products continue to perform reliably through scheduled quality maintenance by competent Smartscan approved engineers.

- Continued compliance with legislation and the appropriate machine safety standards.

- Provide detailed documented listings of Smartscan safety product for the site / machine plus regular input to the maintenance reporting process.

- Opportunity for a safety product use ‘refresher’ for the machine operators.

It is of course a legal responsibility of every company that their employees are working within a safe environment. The Health & Safety at Work Act 1974 is the Statutory Law passed by Parliament that requires employers to provide a safe working environment. In the Provision and Use of Work Equipment Regulations 1998 (PUWER) the subject of maintenance is directly referenced within the Act and the employer’s responsibility with regard to maintenance and ensuring that machinery is kept in safe working order.

In order t- meet with these requirements a new risk assessment should be carried out after any changes to ensure that any new risks are identified and safeguarded against. In the HSE report ‘Out of Control’ 20% of the incidents investigated were attributed to changes after the machine had been commissioned.

A regular maintenance package provides a useful safeguard in helping to identify possible changes to the machine / safety system. It is not uncommon for modifications t- be made t- machines during their life span, typically to make it friendlier for the operators. Over time these modifications can become part of the standard operating procedure. Should these changes lead to a safety incident the company can find itself exposed to the full weight of the law, as any changes will make the original risk assessment null and void.

Another driver for maintenance within the field of machine safety comes from the various machine safety ‘Standards’ e.g. EN 60204-1, IS- 12100, EN 954-1. One of the more recent of these has been IEC 61508 and its sector specific standard IEC 62061 for Machinery which encourage a life cycle approach t- machine safety. Looking at machine safety solutions from initial concept through t- Maintenance / Repair and eventual Decommissioning / Disposal. The HSE view the use of such standards as good practice by an employer in trying to achieve their machine safety objectives.